Safety Talk About Line of Fire Hazards

When working with tools or around objects that can cause injury, it’s important to be aware of your surroundings and keep yourself safe. One hazard to be aware of is the “line of fire.”

Essentially, the line of fire is when a person is located in the path that a moving object would take if it were to fall or otherwise move. If you are in the line of fire, you could be seriously injured.

The three main categories of line of fire hazards are:

- Caught-in or between, such as when a worker stands between a wall and a reversing truck and is crushed

- Released energy, for example where a worker could be hit by a flame shooting from an opened furnace door

- Struck by, like being at risk of being hit by a falling tool from a high platform.

When you’re working around objects that could fall or come into contact with you, it’s important to be aware of the line of fire and take steps to protect yourself.

- Around 27% of deaths in the workplace relate to line of fire incidents

Why is line of fire hazard safety important?

Line of fire hazards are important to understand because they involve the worker putting themself into a dangerous situation. Being in the line of fire might not always be avoidable, but understanding the risks and being able to recognize, evaluate and control them could save the worker from injury or death.

OSHA regulations for the line of fire hazards

There are a number of OSHA regulations that relate to line of fire hazards. They include:

- 1926.1424 – Work area control for cranes and derricks in construction

- 1926 Subpart G – Signs, Signals, and Barricades

- 1926.100 – Head protection

- 1926.451(h), Falling object protection

These help to both prevent line of fire incidents and protect those workers who must enter the line of fire as part of their regular work duties.

By following these regulations, employers can help ensure that their employees are as safe as possible from the line of fire hazards.

Line of Fire Hazards

- If you’re working with chemicals, you could be exposed to fumes or splash back caused by a leak or from removing a lid at the wrong time.

- If you’re using power tools, there’s a risk of flying debris for anyone in the vicinity as the tool works its way into the surface, dislodging parts of that surface.

- There are hazards presented by gravity, causing items to drop onto the worker from higher platforms

- Moving machinery and vehicles can cause struck-by or caught-between injuries

- Objects coming into contact with you as they move or are moved around the site

- Being struck by an object that is dropped, thrown, fired, pushed, released or which moves in any other manner.

Line of fire hazards toolbox talk

How to avoid “Line of Fire” injuries

You should try to eliminate hazards when working in an area with known hazards. You cannot eliminate all hazards, but you should do your best to protect everyone.

Discuss safety and other issues regularly in the company. Employees need to be aware of dangers so they can avoid unnecessary injuries. Employees and their surroundings can be better protected if everyone is alert.

Precautions

You should take precautions to ensure that there are no hazards in certain areas. This means putting up barriers and signs to keep people away from the most dangerous areas. Here are some examples of what you could do:

- To prevent nails, drills, and other objects falling from high places, place toe boards along the edge

- Put guards and barriers in place around swinging and moving machinery

- To keep people from dangerous areas, use physical barriers

Each employee must have a working knowledge of the work area. It is important to know where there are high risks for injury and hazards. The power of knowledge is key to keeping everyone safe.

Protect yourself in these ways

- Toeboards, guardrails and midrails must always be present on scaffold platforms

- Employers who work at high elevations should use safety harnesses/safety nets

- It is important to always have a safe way out of a trench

- Do not move a load on a crane directly over individuals

- It is important to have a written spill control plan

- All forklift operators must be properly trained, certified, and capable

- Ban all horseplay when operating major equipment

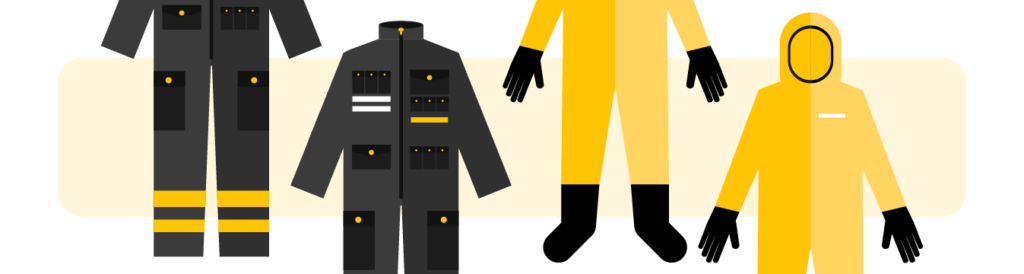

- All workers should wear proper PPE at all times

What does proper PPE consist of?

You should always wear PPE when working in hazardous environments. You need to know what PPE is required for your job. All of these items are designed to keep you safe and protect you while you perform different tasks. These are some examples of PPE:

- For hand protection, use snug fitting gloves

- Head protection with hard hats

- Safety glasses and a face shield to protect your eyes and face

- Slip resistant soles and steel toe boots, as well as puncture resistant soles are available.

- Burns from hot steam or flames

- Crushed bones

- Head injuries

- Pinched fingers or hands

- Death

Questions to employees

- Are there any line of fire hazards on your site?

- What can you do to reduce the risks involved in the line of fire hazards?

Promote line of fire hazard safety with this email template

Hi everyone,

Today I want to talk to you about the line of fire hazards. A line of fire hazard is any hazard that could cause an object or substance to be projected into your body. This could include things like flying debris, moving machinery, or even chemicals and liquids.

There are a few things you can do to protect yourself from the line of fire hazards.

- First, always be aware of your surroundings and make sure you know where the potential hazards are.

- Second, wear the proper personal protective equipment (PPE) for the job. This might include things like safety glasses, gloves, or even a face shield.

- Finally, if you’re ever in doubt, don’t hesitate to ask a supervisor or safety professional for help.

Thanks for your time and stay safe out there!

Video on Line of fire hazards

Line of fire hazards meme

Conclusion

Working in the line of fire can be dangerous, but there are steps that employees can take to stay safe. By being aware of the hazards and taking precautions, employees can minimize the risks associated with working in this environment.

By using the tools and resources available, safety managers can help to raise awareness of line of fire hazards and ensure that all employees are aware of the dangers.